Working Advice

- Remove the battery from the power tool before carrying out work on the power tool (e.g. maintenance, changing tool, etc.). The battery should also be removed for transport and storage. There is risk of injury from unintentionally pressing the on/off switch.

- This power tool is not suitable for bench-mounted use. It must not be clamped into a vice or fastened to a workbench, for example.

- Wear protective gloves during work. Make sure that cut sheet parts are not bent towards your body. Sharp burrs develop on cut sheets; these can cause injury. When necessary and while wearing gloves, press bending sheet parts away from your body.

Apply the machine to the workpiece only when switched on.

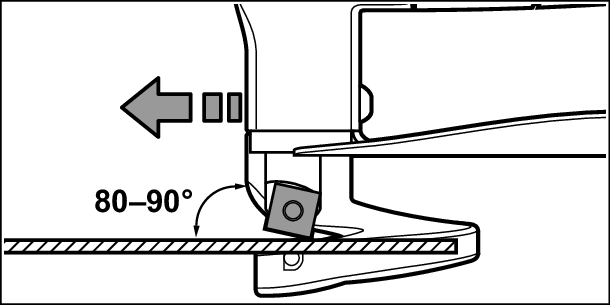

Guide the power tool at an angle of 80° to 90° to the surface of the sheet metal and do not tilt it to the side.

Guide the power tool evenly, pushing it gently in the cutting direction. Applying too much pressure to the power tool will significantly reduce the service life of application tools and can damage the power tool.

When cutting curves, make sure not to tilt the power tool laterally and work with low feed rate only.

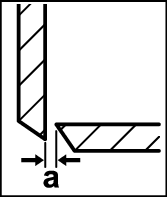

| The cutter clearance a (gap between the cutters) depends on the sheet thickness dmax to be cut. |

The clearance a between the cutters should be 10 % of the maximum sheet thickness (e.g. 0.1 mm cutter clearance for 1 mm sheet thickness).

For softer or more ductile materials, the clearance a must be decreased; for harder or more brittle materials, it must be increased.

Loosen the fastening screw (10) for the bottom cutter. Adjust the requested cutter clearance a with the set screw (9) for the bottom cutter. The upper cutter (7) and the bottom cutter (8) may not touch each other.

Check the clearance with a commercially available setting gauge. Retighten the fastening screw (10) for the bottom cutter with a tightening torque of 3–4 Nm.

In normal conditions of use, the power tool cannot be overloaded. If the power tool is overloaded or the battery temperature is outside the permitted range, the stroke rate is reduced or the power tool shuts down. When the stroke rate is reduced, the power tool will not run at the full stroke rate again until the battery temperature is back within the permitted range. In the event of automatic shutdown, switch off the power tool and allow the battery to cool down before switching the tool on again.